Home » Intelligence for cranes » Overload protection

Overload protection

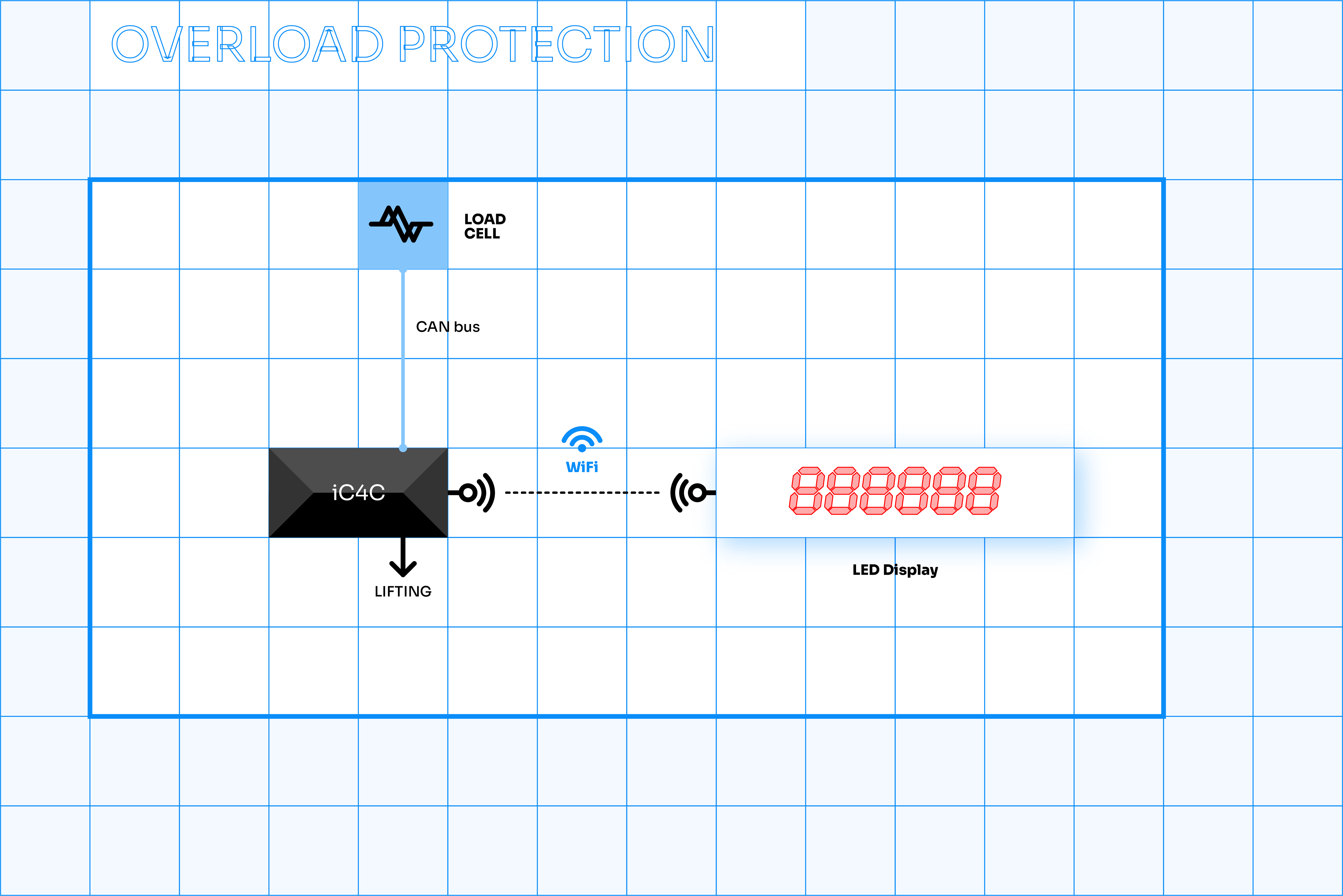

The pro-version of the i-C4C GO is certified Performance Level d for overload protection. The load cells are available in various types, including load pins and clamp-on load cells. All of them have an integrated analogue-to-CAN converter, making calibration easy. A range of complementary functions can be added, including slack rope detection and shock load protection.