Home » Intelligence for cranes » Zone protection

Zone protection stops the hoisting system entering a designated area. A combination of multiple protected zones can be programmed into i-C4C, and the protections can also be condition-based. Intelligent use of these options can provide automatic protection for the entire workplace and its workers.

Zone protection stops hoisting systems entering a designated area. A combination of various protected zones can be programmed into i-C4C, and the protections can be condition-based. Intelligent use of these options can provide automatic protection for the entire workplace and its workers.

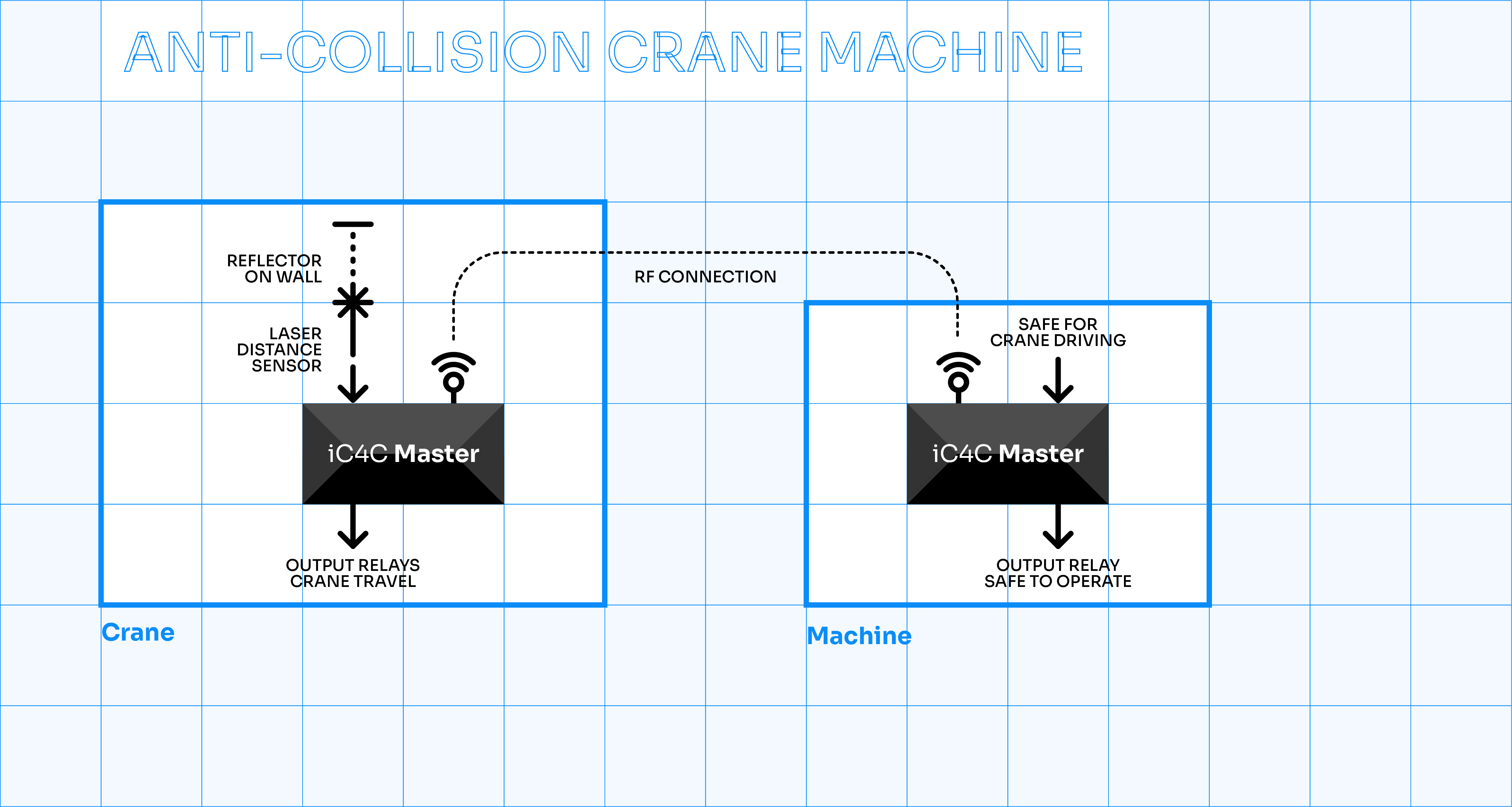

Condition-based protection makes certain areas off-limit under particular conditions only. A remote-control module communicates the condition to the central i-C4C module via a secure radio frequency (RF) connection. To guarantee absolute safety, any disruption in the communication will bring every movement to an immediate safe state. A typical example is a gate through which the crane is only allowed to pass on condition the gate is open.

Through laser sensors, the position is detected on one or two axes, with the position then checked against the activated restrictions. Multiple zone restrictions can be added as required. If there is only one restricted zone, the laser sensors can be replaced by limit switches.

The diagram shows an application where a designated zone is restricted by the condition of another device in the workshop (e.g., a tipping station). The master i-C4C controls the movements of the crane and hoist, with laser position detection as an input value. A second i-C4C unit controls the movement(s) of the machine that can come into conflict with the crane or hoist (e.g., tipping up). Both controls communicate through a radio frequency (RF) connection. When the crane or hoist approaches the protected zone, it requests permission from the machine controller. If the machine seeks to start a protected movement, it will first ask clearance from the crane controller.